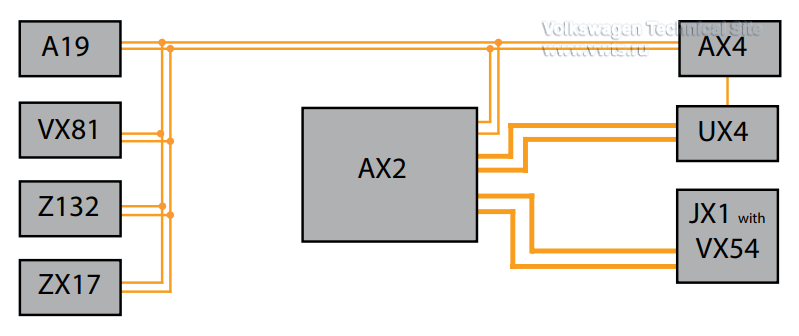

The VW ID.4 Wiring and Connector Concept

Key

A19 Voltage Converter

AX2 High-Voltage Battery 1

AX4 High-Voltage Battery Charger 1

JX1 Electric Drive Power and Control Electronics

UX4 High-Voltage Battery Charging Socket 1

VX54 Three-Phase Current Drive

VX81 A/C Compressor

Z132 Heating Element (PTC) 3

ZX17 High-Voltage Heater (PTC)

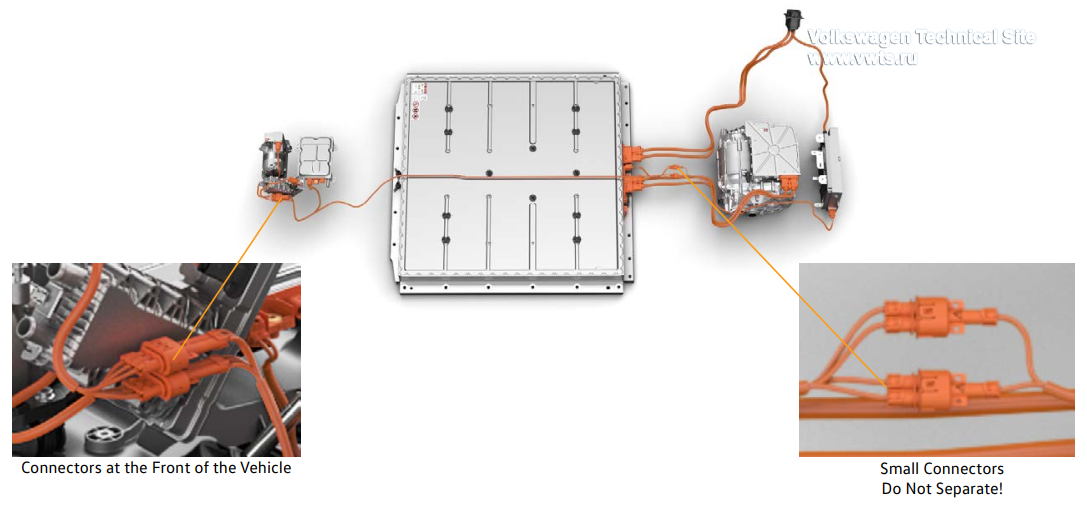

Wiring Junctions

The components do not require power distribution panels. They are replaced by wiring junctions in the high-voltage wiring harnesses.

The wiring junctions in the rear area connect AX4 High-Voltage Battery Charger 1 to AX2 High-Voltage Battery 1 and the high-voltage components in the front of the vehicle.

The wiring junction in the front of the vehicle connects the Z132 Heating Element (PTC) 3, the VX81 A/C Compressor, the A19 Voltage Converter and the ZX17

High-Voltage Heater (PTC) to the components in the rear of the vehicle.

The small connectors in the high-voltage circuit are glued during production and cannot be separated.

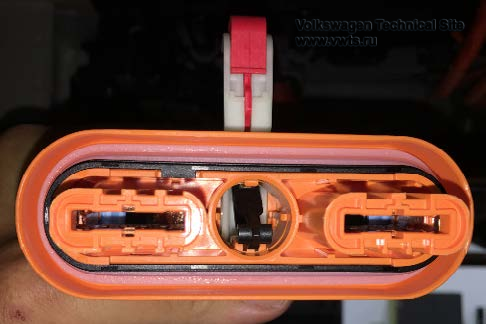

Connector Concept

The connectors of high-voltage components are required to protect against foreign objects touching the contacts that carry life-threatening voltage.

This is known as Ingress Protection (IP).

The connectors on MEB vehicles have been designed with a higher ingress protection standard to ensure a greater degree of protection against penetration of a solid object (such as a finger).

Because of this new connector concept with heightened touch protection, there is no longer need for a “pilot line” between all components in the high-voltage system.

The electrical connectors are a new component

developed for advanced accidental contact protection.

All HV wires in the Volkswagen ID.4 are connected mechanically.

No screw connections on the wires are used.

To ensure that the contacts still have the necessary

cross-sections, the connectors are wide.

Table of Contents

High-voltage System Overview

Wiring and Connector Concept

High-voltage System Components

Thermal Management

High-voltage Safety Concept

Driving Mode Selection

Wiring Concept

A new high-voltage wiring concept is being use in Modular Electric

Drive Matrix (MEB) vehicles.

Thanks to the revised electromagnetic compatibility (EMC), shielded

cables are not necessary.

The EMC filters are adapted to the individual requirements of the

different high-voltage components.

They can be made of capacitors, restrictors or more complex

circuitry.

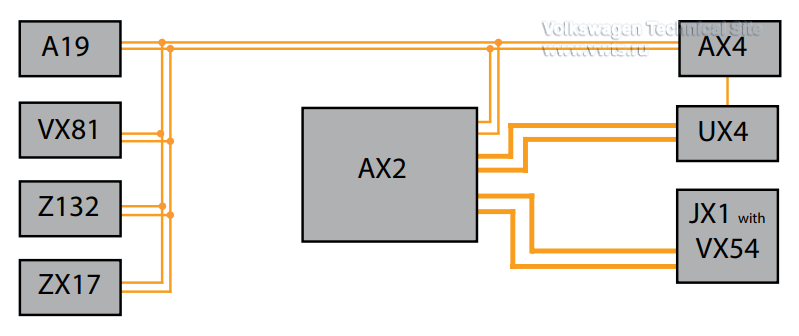

Key

A19 Voltage Converter

AX2 High-Voltage Battery 1

AX4 High-Voltage Battery Charger 1

JX1 Electric Drive Power and Control Electronics

UX4 High-Voltage Battery Charging Socket 1

VX54 Three-Phase Current Drive

VX81 A/C Compressor

Z132 Heating Element (PTC) 3

ZX17 High-Voltage Heater (PTC)

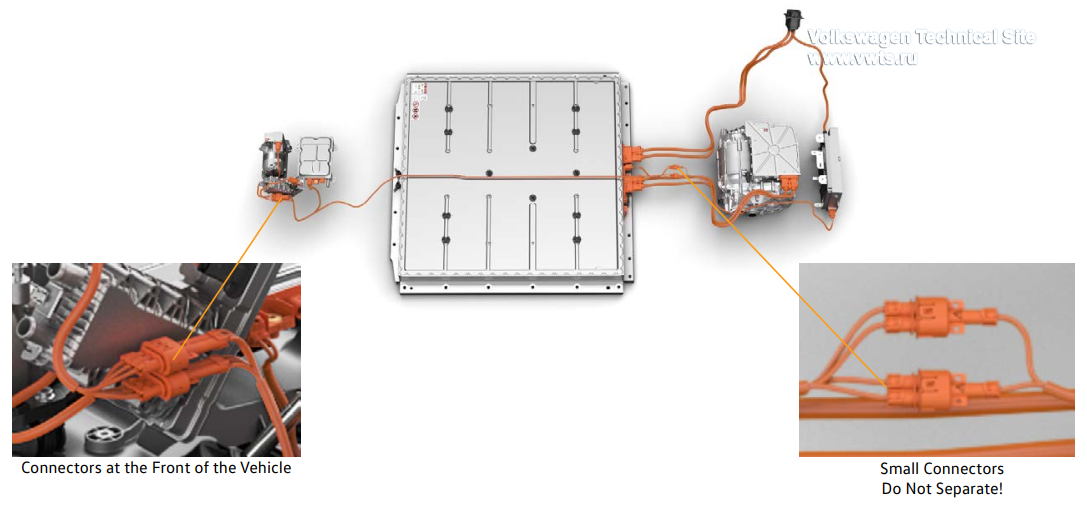

Wiring Junctions

The components do not require power distribution panels. They are replaced by wiring junctions in the high-voltage wiring harnesses.

The wiring junctions in the rear area connect AX4 High-Voltage Battery Charger 1 to AX2 High-Voltage Battery 1 and the high-voltage components in the front of the vehicle.

The wiring junction in the front of the vehicle connects the Z132 Heating Element (PTC) 3, the VX81 A/C Compressor, the A19 Voltage Converter and the ZX17

High-Voltage Heater (PTC) to the components in the rear of the vehicle.

The small connectors in the high-voltage circuit are glued during production and cannot be separated.

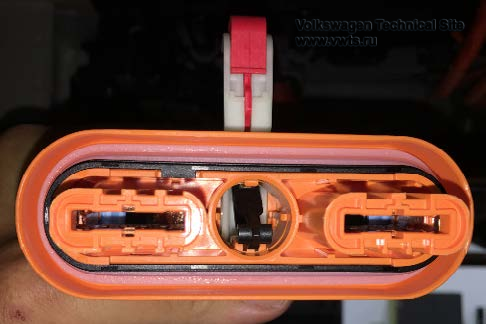

Connector Concept

The connectors of high-voltage components are required to protect against foreign objects touching the contacts that carry life-threatening voltage.

This is known as Ingress Protection (IP).

The connectors on MEB vehicles have been designed with a higher ingress protection standard to ensure a greater degree of protection against penetration of a solid object (such as a finger).

Because of this new connector concept with heightened touch protection, there is no longer need for a “pilot line” between all components in the high-voltage system.

The electrical connectors are a new component

developed for advanced accidental contact protection.

All HV wires in the Volkswagen ID.4 are connected mechanically.

No screw connections on the wires are used.

To ensure that the contacts still have the necessary

cross-sections, the connectors are wide.